3PL Logistics for Distributorship in the Southeast

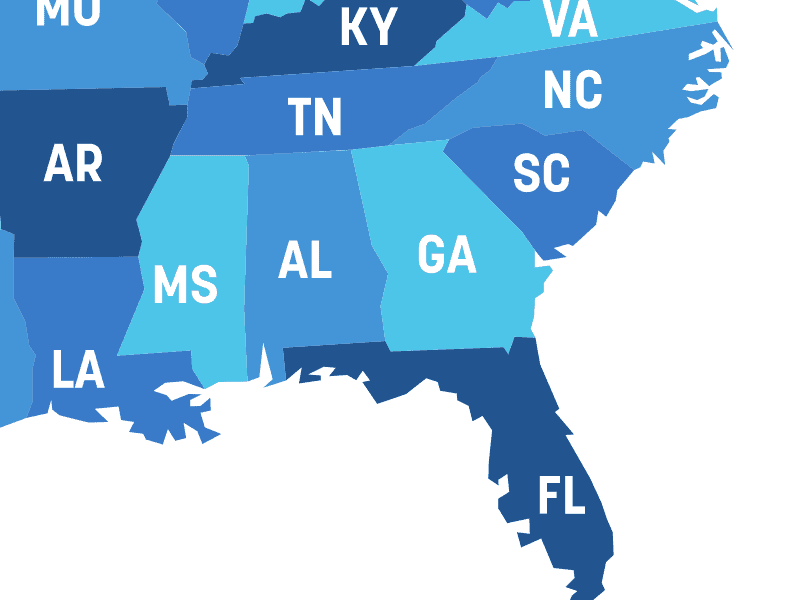

Distributorships move bulk volumes of goods throughout the Southeastern USA to fill retail stores in the region and can handle smaller B2C orders.

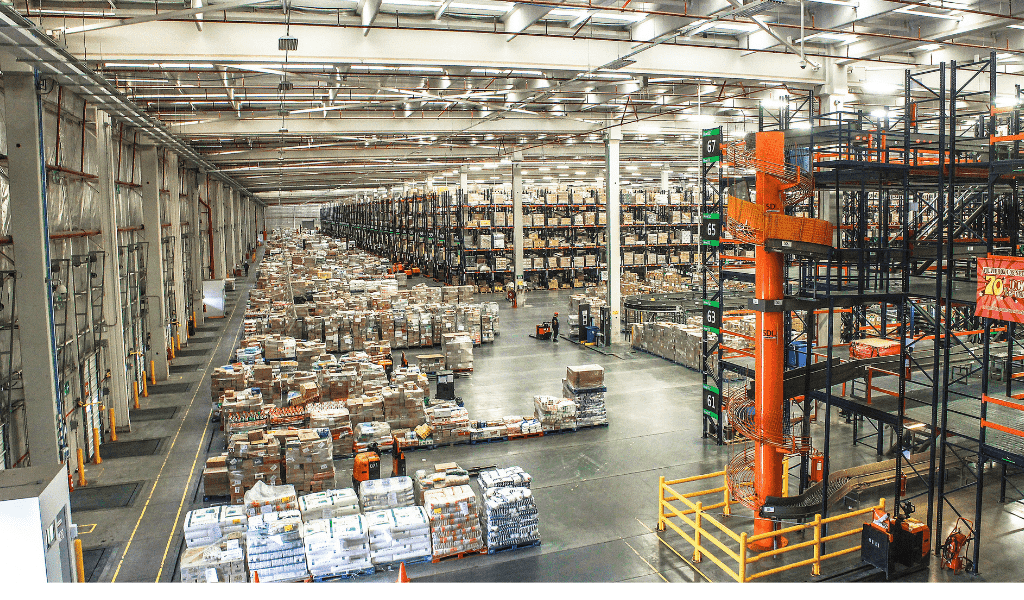

To support business growth, overflow, peak season and other supply chain challenges, distributors often use third-party logistics (3PL) companies to help take the operations load off your internal team’s shoulders. 3PL logistics providers are experts at warehousing, distribution and supply chain operations. They provide flexible, on-demand scaling to meet your operational needs.

3PLs handle the storage and movement of goods from Point A to Point B, while your Team focuses on your product and other core business functions.

Why use a Distributorship in the Southeast USA?

Business reasons to use or start a distributorship in the Southeast USA vary by company, the size of the product line and other custom supply chain requirements. Here we will discuss a few examples of how distributorships in the Southeast can be helpful to distributor’s supply chains.

Distributorship from a Single Warehouse Facility

Distributorships can service customers far and wide from one location in the Southeast USA. A single distribution center can ship products to customers all-around-the-globe. The caveat is it will not always be the cheapest and lead times may be long; especially as the model scales.

This logistics model fits companies for several reasons, such as smaller manufacturer Brands with lower volumes who are looking for minimal supply chain costs and planning for their smaller inventory quantities. This supply chain model also works great when

- lead time and shipping cost expectations are not top-of-mind for customers

- most your distributorship customers are located near a geographic-point-of-interest

- your business first moves to a distributorship model. Start with one facility and scale up (quickly)

- & other models

Southeastern States Serviced from our nearby facilities include: AL, FL, GA, AR, KY, LA, MS, NC, SC, and TN.

Distributorship using Multiple Warehouses

To effectively manage their distributorship, many supply chains need multiple warehouses, especially when customers are distributed across the globe. Although there are many reasons you may need multiple distribution centers, such as when you carry a very heavy or oversized product that ships to customers with less than truckload (LTL) carriers.

Reasons distributorships use multiple warehouses:

- Expand a product line to a new geographic audience. You likely need new 3PL logistics partners near the customers, that your current distributorship cannot handle.

- For example, European Brands entering the US consumer market through Amazon FBA and department stores. These folks must overpay to ship one-off orders to customers in the USA from overseas facility.

- Improve customer experience

- When customers are geographically separated. It can be important to get goods to them quickly. To do this, at a reasonable price it may be necessary to have multiple distribution centers throughout the USA for the same products.

- To save customers money on shipping, when the cost is passed-through to customers receiving goods half-a-world-away.

- Reduce operating expenses by storing slow moving or overflow goods in low-cost, less frequently used storage.

- Companies looking for opportunities to reduce capital expenditures and Op Ex by outsourcing the distribution workload to partners.

Managing the more complex supply chain

- Research and plan your Southeastern distributorship strategy to align with your company objectives and realistic growth forecasts.

- Have your internal-team distribute orders to the correct warehouse. Don’t rely on each 3PL logistics partner to share information between each other.

- Automate this in your ERP system when possible to improve speed and the quality of data exchanged between companies.

- Track your inventory, POs and all order and financial data independently of the facilities where goods are stored.

- You must maintain control of the source of truth and ensure everyone else syncs their data and systems with yours

Supply chains get exponentially more complex as touch-points and facilities are added.

Don’t Go It Alone

Running the operations-end of a Southeastern distributorship is a big commitment and requires skills, resources, and strong operations leaders who have capacity to take on a new project. When your internal team focuses on business growth and product improvement, the distribution operation is a big undertaking for the team. That’s where 3PL logistics providers can help you receive, store and ship products.

How can a 3PL Logistics Partner Help your Distributorship?

As mentioned before, 3PL logistics partners help distributorships by offering outsourced scalable and efficient distribution solutions. These partners take care of a single job in the supply chain, such as storing overflow goods. Or they can be deeply integrated into your supply chain. When 3PL logistics partners handle large chunks of work in your distribution supply chain, your team is relieved from the stress, deadline pressure and staffing costs of distributing goods.

3PL Logistics Services Offered to Southeastern Distributors

Third party logistics (3PL) providers offer a portfolio of warehouse and supply chain services for distributors with all kinds of needs. 3PLs offer a standard set of inbound, outbound, storage and technology services to clients. They also perform customized projects distributors outsource to 3PL partners.

Here is a list of standard services offered to distributorships by 3PLs, like Warehousing Etc. Remember, this list is not an all-inclusive list; work can be customized to fit your specifications.

Inbound 3PL Logistics Services:

Inbound services are the jobs performed by the warehouse staff when product is received at the warehouse.

Common inbound jobs are receiving:

- Pallets in

- Full truckloads (FTL)

- Less than truckload (LTL)

- Cartons in

- Returns management

- Unloading containers. Learn more below.

- & other coordinated delivery methods

Unloading Incoming Containers

The 3PL provider team unloads and receives containers for distributorship clients who are moving high volumes. These steps are the basic framework for container unload by our skilled warehouse staff.

- Unload goods from 20 foot or 40 foot palletized or loose-loaded goods

- Sort, segregate and count all Stock Keeping Units (SKUS)

- Palletize goods

- Shrink wrap each pallet of goods

- Record any errors or omissions of goods against the purchase order.

- Enter Inbound order information and locations in Warehouse/Inventory Management System.

- Store pallets in permanent location, until shipped out.

Palletize & Store

In a warehouse and distribution center, goods are usually stored on pallets. When goods are receive without a pallet, the warehouse must build a pallet for each SKU to keep the goods separated and findable in inventory.

Palletizing goods is an important step for inventory management, quality control, standardization and optimization of storage space.

Palletization, or palletizing goods, is the process of creating a pallet from loose-loaded goods such as floor-loaded containers. To keep it simple, one SKU goes on a pallet. The SKU units are stacked in uniform rows and columns to make a solid, stackable cube.

To build a pallet, every box or unit must be handled and placed in a logical and engineering-strong pattern, such as pinwheeling. To many peoples surprise, this is not simple and requires experience and skill to build a durable pallet.

After goods are palletized, the staff applies shrink (or stretch) wrap around the entire pallet from top-to-bottom. The stretch wrap is held tight and must cover the base of the pallet and top layer of stacked goods. By wrapping the boxes tightly, across the entire height will ensure the load is locked in place on the pallet. This makes it much safer to move and ship.

The staff may apply location or barcode labels to each wrapped pallet before moving the pallet to a storage location, so the pallet can easily be managed in the system.

Pallet storage is calculated based on a handful of common restrictions: *

- Standard pallets are assumed to be double-stackable, 48″x40″ (wood) pallets.

- Oversized pallets are pallets any pallet over 48″ wide.

- This includes standard pallets with large overhanging box edges.

- Non-stackable pallets are any pallet that can only be single stacked.

- These pallets may be 48″x40″ or less, or they could also be oversized.

- 3PL logistics providers often price non-stackable pallets based on their exact dimensions and can be quite costly for some products.

*Note some 3PLs may also charge you by square footage used per month, or cubic square footage used per month. These charges can be complicated to calculate and uniquely priced per SKU.

Outbound 3PL Logistics Services for Distributorship in the Southeast

Outbound services are jobs performed by the warehouse staff when the product is ready to leave the warehouse.

B2B – Pick, Stage & Wrap

Business-to-business (B2B) orders ship to your business customers following a standard pick, stage and wrap process. First, an order arrives at the 3PL warehouse. The order lists the details of the shipment out such as delivery address, line items, type of shipping, etc.

When B2B orders are placed, they are for larger quantities of goods that ship on pallets. These orders take longer to pick and prepare when pallets of partial goods must be combined to fill an order. This is because pallets must be separated and new, mixed pallets are built to fill an order.

B2B Order Prep Process

- New Order received at the warehouse

- Staff picks all SKUs for the order

- Staff builds and wraps pallets that are ready to ship

- Quality control outbound shipment

- Goods are available in Staging when truck arrives

Potential cost saving tip for manufacturers who sell b2c or omnichannel:

If you have items that sell as individual units, or larger bundles that ship in multiple cartons, it may be advantageous to ask your manufacturer to package the units so they can ship as-is. When manufacturers package goods in ready-to-ship units, the warehouse workload and cost is reduced. Typically, manufacturers have lower labor rates, especially when importing goods from international manufacturing-hubs such as Vietnam, India, Eastern Europe and other similar regions.

D2C/B2C – Pick, Pack & Ship

Direct-to-Consumer (DTC), also called Business-to-Consumer (B2C), orders ship to your non-business customers who typically place orders for fewer items. These smaller orders can be shipped in carton(s).

Fulfilling D2C orders is a lot different from distribution. For instance, D2C orders often only have one item. To pick and prepare an order for only one item requires a lot of motion and materials. The shipping costs add up quickly when volume is low, so its important to find the right market for your product to scale.

For many Brands, their extremely high profit margin, moving into new D2C markets, and/or strong customer Demand makes the D2C extremely appealing. In the right markets, with the right product the volume of orders per day makes up for the fewer items per order. In this case, you’ll need the right partner to help scale your supply chain.

Fortunately, the D2C order fulfillment process is much faster than B2B order fulfillment, since there are less items and weight to pick per order.

D2C Order Prep Process

- New Order received at the warehouse

- Staff picks all SKUs for the order

- Pack goods in a carton and/or apply shipping label

- Quality control outbound shipment

- Package is ready for courier pick up

Load for Delivery

After the warehouse prepares an order for shipping, there is a brief wait for the shipping courier’s driver to arrive. During this time, it sits in the staging area waiting for pickup.

Most couriers pickup deliveries in the afternoon between 1-4pm. The exception is FTL drivers for large B2B orders; their pickup schedules vary based on availability.

Pickup Duties of the warehouse:

- B2B orders

- Shipping via Less than truckload (LTL) usually require the warehouse to load 1+ pallets with a forklift or manual pallet jack.

- When shipping via Full truckload (FTL) requires the warehouse to load ~18+ pallets into a 53′ dry van semi trailer using a forklift.

- Shipping via parcel courier (such as UPS ground) requires the warehouse to place cartons in designated pickup area and print an end-of-day summary per pickup. This is usually extremely costly and inefficient for large B2B orders.

- D2C orders

- Ship via standard Domestic or International courier requires the warehouse to place envelops and cartons in a designated pickup area.

- Often a rolling bin or carrying bin will be provided by the courier such as USPS.

- When the courier’s pickup driver arrives they will load parcels into their truck. When the warehouse is staffed properly and there are a lot of parcels, the warehouse staff helps the driver load.

- Ship via standard Domestic or International courier requires the warehouse to place envelops and cartons in a designated pickup area.

Get Started with 3PL Logistics

To get started with a 3PL logistics partner to launch or expand your distributorship, simply:

- Determine the scope of work you need help with.

- Get in touch with our logistics specialists.

- Receive your free, customized quote.