Warehouse Logistics Summary

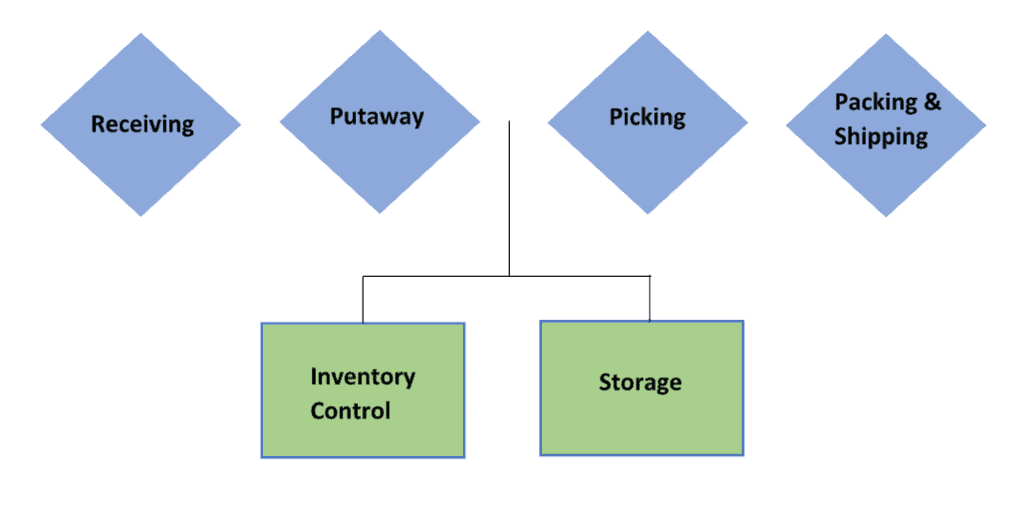

- The 6 functions of warehouse logistics are: Receiving, Putaway, Picking, Packing and Shipping, Inventory Control, and Storage

- To achieve ideal warehouse logistics operations, Inventory Control must be considered while developing all processes and functionalities.

- Cycle Counts or Full Inventory Counts should be used to ensure Inventory Accuracy

Warehouse Logistics Details

We will review the 6 main functions of all warehouse logistics operations: Receiving, Putaway, Picking, Packing and Shipping, Inventory Control, and Storage. We discuss each warehouse function, present the general Workflows of each warehouse function, and discuss why the function is important in the operation.

1. Receiving Warehouse Logistics

The receiving process lays the foundation for the accuracy of inventory during its life cycle in the warehouse. The Receiving process creates an itemized review of materials received and is the first time goods are physically handled by your own warehouse.

The receiving process follows the below general workflow, customized per requirements.

- Freight delivered to warehouse

- Staff identifies unique identifier in Warehouse Management System (WMS) to receive freight against (PO#, SO#, other reference)

- Staff physically confirms receipt items and quantities against expected, noting any discrepancies or damages

- Using PC or RF Scanner, staff adjusts WMS receipt to match received products and quantities

- Additional labeling, other Value Added Services (VAS), or data acquisition/entry (such as weight/dims collection) may occur during Receiving

- Stage or identify products to be Putaway (unless crossdocking, then place in respective crossdock location)

Accurate Receiving is important because this is the opportunity to identify Overages, Shortages, and Damages (OS&D) in order to file a claim with the carrier or vendor. Undoubtedly, missing any OS&D will lead to inventory inaccuracy and increased likelihood of later supply chain disruption. Warehousing best practice is to utilize RF Scanners, or comparable technologies, to further improve inventory accuracy and real time inventory tracking.

2. Putaway Logistics

Closely intertwined with Receiving, Putaway is the final stage of inbound processing. Putaway is the process of physically, and systematically, placing products into their appropriate final storage locations.

Putaway follows the below general workflow, customized per requirements.

- Staff selects Product to putaway from Putaway Staging area

- Generally Pallets or Carts with Product ready to be putaway

- Using RF Scanner, identify what cart/pallet/job you are putting away and scan unique identifier to begin Putaway

- Picker travels to location to place product for storage

- Ideal best in class systems tell staff where to place product, but many warehouses still have staff place product where they know there is empty space (with some criteria applied)

- RF Scan Product being putaway and Location where the Product is putaway

- Continue process (go to location and place stock) until entire order, pallet, cart, etc is complete

Criteria Effecting the Putaway Location of Inbound Product.

- Weight and dimensions of product/pallet being putaway

- Stowability of Product (ie fragile, stackable, etc)

- Transaction volume (HOT items placed close vs NOT far away)

- Quantity received

- Value of product

- Pick Type of Product (single pick, batch pick, cluster pick, zone pick, etc)

Accurate Putaway is imperative in the warehouse operation, ensuring that Product can be easily located exactly when it is needed. It does no good to have the correct total quantity of a Product within your facility if you cannot locate it when it is needed, especially when it is needed for a current customer’s order! Re-evaluate, audit, and monitor your putaway processes to improve inventory accuracy.

3. Picking in Warehouse Logistics

Similar to how Receiving lays the foundation for an accurate inventory, Picking lays the foundation to accurately fulfill a customer’s order. Picking is the process of gathering Products to fulfill a client’s order request.

Picking follows the below general workflow, customized per requirements.

- Picker is assigned Pick(s)

- There are many pick methods, each operation is unique in what is most efficient for their needs

- Zone picking, batch picking, single order picking, wave picking, and more

- Using RF Scanner, or similar, begin picking by entering the Unique Pick Identifier (batch #, Order #, SO#, Pick #, other reference)

- Picker is routed through the Pick Path (hopefully based on optimization logic) to fulfill the Pick, scanning Products and Locations as they progress

- Picked items may be placed in totes, pallets, carts, shelf, etc during pick

- Fully picked orders delivered to next phase of process

- Picked orders may be delivered to a Quality Control area, Packing/Shipping area, or directly to outbound staging (if pick to label operation) depending on operation

Criteria Effecting Pick Methods in Warehousing.

- Limitations/abilities of current Warehouse Management System (WMS)

- Volume of Orders

- # of Product Lines per Order

- Type of storage media (shelving vs racking vs ground pallet storage)

- What the Packing and Shipping Process looks like (closely intertwined to Picking)

- Product require extra attention during packing? Transportation Management System (TMS) capable of providing shipping labels before items are picked? Much more!

- Warehouse Layout

Picking must be done accurately, with quality control measures in place post-picking, to achieve customer order fulfillment accuracy near 100%. Correcting an inaccurately picked item within the warehouse is timely and costly. However it is significantly more expensive to correct the error if the customer identifies the inaccuracy upon receipt – plus you may lose that dissatisfied customer!

4. Packing and Shipping Warehouse Logistics

The final process in a Product’s life cycle is Packing and Shipping. Packing and Shipping is the process of packaging goods and labeling exterior cartons for carrier pickup.

Packing and Shipping follow the below general workflow, customized per requirements.

- Outbound staff selects Order(s) to ship from Packing Staging area

- May be 1 order at a time or many at once

- Scan order in system (WMS, TMS, or both) for Packing and Shipping

- Quality Control Process

- Physically confirm that correct Products and Quantities are present

- Last opportunity to ensure accurate order fulfillment

- Adequately package all items for shipment

- Shipping method often dictates packing method (polybag, box, pallet, loose, etc)

- Generate and apply shipping label

- Often much advancement opportunity in a warehouse’s label generation process – integrate and automate!

- Apply shipping label(s) and documentation to package/pallet/shipment

- Stage for later carrier pickup, and load the order in full upon carrier arrival

Examples of Quality Control Processes.

- Paper based – physically confirm correct Products and Quantities picked

- RF / USB Scanner – Packer scans each item before/during packing

- Weight tolerance check during Shipping

- That is based on system data; we expect the shippable unit will weigh X pounds. So if during shipping the weight is not within the defined tolerance range, then the user will be prompted to take action

- Dimension tolerance check during Shipping

- Similar to Weight tolerance based on system dimension data

Packing and Shipping is a major focus of warehouses, as it often becomes a bottleneck since Order Processing Time must be as short as possible to fulfill customer expectations. While improving efficiency and output of Packing and Shipping, it is imperative to develop the process to ensure Order Accuracy is maintained. Do NOT sacrifice quality! It is important to note, depending on the warehouse operation Packing may be combined with the Picking process.

5. Inventory Control in the Warehouse

Inventory Control is an integral part of all warehouse operations. You can guarantee the inventory at the warehouse is accurate and up-to-date with a well defined Inventory Control process. All operational functions in the warehouse play a role in maintaining Inventory Control; additionally facilities often have dedicated teams auditing and correcting inventory counts continually. Cycle Counts and Full Inventory Counts are tools associated with maintaining Inventory Control. Cycle Counts occur continually while normal operations continue, but Full Inventory Counts occur periodically and require all product movement to cease until a full accurate count is completed.

Full Inventory Counts follow this general workflow, customized per requirements.

- Shutdown all inventory movements, completing all Product Movements in the Warehouse (physically and systematically)

- Ensure all inbound and outbound orders that have been physically processed, have also been processed in WMS

- Break warehouse team into groups to count (sometimes 1 person team okay)

- Teams are assigned areas to count

- Assign small-medium areas to count, then teams check in for more areas as needed

- Teams count assigned areas, recording counts of product per location

- Teams often using RF Scanners to record counts

- Otherwise have to do paper-based which is hard to achieve a Blind Count

- Blind Count is IDEAL

- Team reports back once completed and receive next Count Assignment

- After areas are Counted, the Manager/Lead reviews all Variances

- Manager assigns DIFFERENT Team to recount the troubled Products and/or Locations

- If 2nd team counts same as 1st team, make inventory adjustment to match physical count. If there is still a question, then the Manager or Lead must address.

- Important to check system transactions to see if an Inbound or Outbound job Saving/Finalization will correct the variance, rather than creating an adjustment which is not linked to a specific inbound or outbound job

- Always count ALL locations of a product before adjusting a Product’s count in 1 location

- Once all Locations and Products are counted and corrected, the warehouse reopens for transactions

Cycle Counts follow this general workflow, customized per requirements.

- Inventory Control Team is assigned areas to count each day, week, or some time period

- Cycle Count means inventory is continually being counted, cycling through all inventory to achieve a count of entire facility over some time period

- Cycle Count Team begins counting assigned locations, often with RF Scanner

- Enter Cycle Count Job # or Location to begin systematic count

- If paper based Cycle Count process, must be VERY careful to ensure inventory variances are actual

- High risk of counting against out-of-date data if using Paper Based Cycle Count

- Scan / Enter Quantities of counted products and locations, confirming discrepancies along the way

- Cycle Count Lead assigns 2nd Count Team to recount Variances, and reviews themselves if needed

- Inventory errors corrected as they are identified

Inventory Control is an integral part of warehousing. Accurate inventory in the warehouse ensures that all warehouse operations run as smoothly and efficiently as possible. While it is the Inventory Counters’ task to ensure inventories are accurate at time of counting, it is the entire facility’s responsibility to ensure that Inventory levels stay accurate. This is achieved by building your processes and culture around Inventory Control.

6. Storage Warehouse Logistics

A core purpose of warehousing logistics is Storage; many types of warehouses exist primarily to store inventories and safety stock. This is the function of storing the materials at the facility between the time the Product arrives and the time the product departs.

Storage Considerations include Type of Storage Media and Supporting Equipment.

- Storage Media Types

- Shelving

- Racking (Single Deep and Double Deep)

- High Pile Pallet Ground Storage

- Cantilever Racking

- Carousel

- Flow Rack

- Pushback Rack

- Equipment – Supporting Storage Media Types

- Sit-down forklift

- Stand-up Reach or Double Reach

- Cherry Picker

- Line Driver / Turret Truck / Swing Reach

- Combilift or Aisle-Master

- Ladder

- Pallet Jack

- Carts

- Bins / Totes

Storage is a key factor of warehousing costs, especially in cities and places where warehouse facilities’ cost per sq ft is at a premium. Additionally, the types of Storage Media used impact the warehouse processes and equipment needed to fulfill those processes. Special attention should be given when selecting Storage Media Types, in order for the operation to reach its most efficient state.

Due to rising warehouse demands, many facilities are growing upward (vertically) to expand their cubic capacity rather than taking on additional square feet. It is important to note that automated systems can enable vertical warehouse growth that was previously impractical. Micro-warehousing (perfect case for automated vertical warehouses) is also gaining a foothold in densely populated cities to achieve same-day deliveries.

Conclusion

Warehouse logistics includes 6 key process areas: Receiving, Putaway, Picking, Packing and Shipping, Inventory Control, and Storage. Each of these processes can impact each other, and all impact the Inventory Accuracy of the facility.

A quality Receiving Process lays the foundation for an accurate inventory life cycle, since it is the first time the warehouse is physically handling the goods. Putaway must be done correctly to ensure Products can be located when they are needed. Accurate Picking is the key to ensuring your customer’s orders are being fulfilled 100% accurately. Packing and Shipping is often a bottleneck, and requires constant improvement to meet volume and output expectations of the customer while ensuring Quality Control. Inventory Control is the responsibility of the entire staff and must be considered when developing processes. Storage is a core function of the warehouse, and ultimately drives a significant share of warehouse costs.

What pain points are you struggling with in your Warehouse Operation?

Comment below!