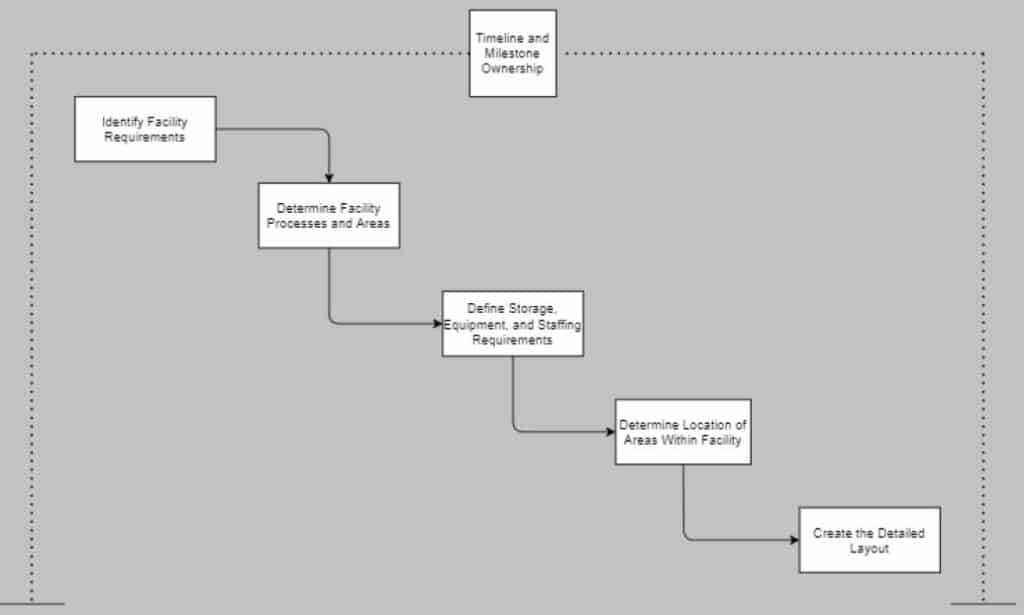

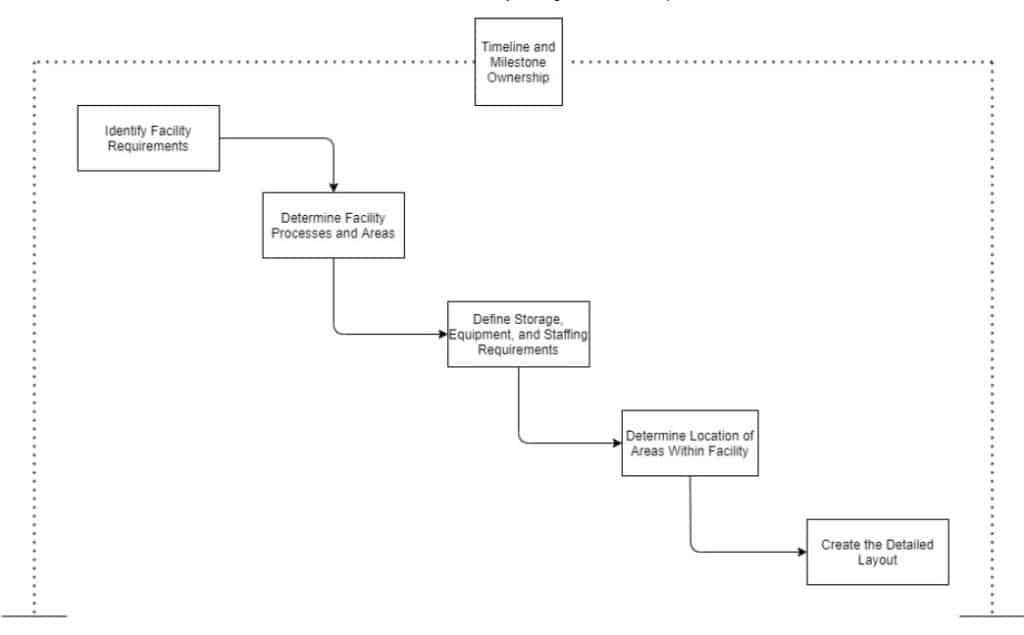

Key Takeaways:

- 6 Components to Successful Facility Planning and Layout Design

- Goal of Layout design must be to allow optimal flow within and between areas, because flow has a direct impact to daily operation costs

- Determine Geographic and Facility requirements of your operation before committing to a facility

- The Final Detailed Layout must be created with enough details to be implemented, often including labels and measurements

The Details

An optimal facility layout is vital to running an efficient operation. Thorough evaluation and review is required during facility planning and layout design because the final layout directly impacts labor costs and storage density. We review the methodology to design the ideal layout design for your warehouse operation.

Table of Contents

I) Identify Facility Requirements

The first step to standing up a new warehouse is selecting the new building. To ensure a successful opening, each operation’s unique requirements for a facility must be considered. There is a vast range of requirements to be considered before selecting a facility, from geographic location to number of parking spaces. Selecting a facility that does not meet all requirements is not only costly, but can cause significant delays to opening the operation.

Commonly Considered Facility Requirements

- Geographic Location

- Proximity to Supply Origin

- Proximity to End Destination

- Proximity to Ports, Airports, and/or Rail Stations

- Availability and cost of skilled staff

- Building Features

- Ceiling Height

- Square Footage

- Number of Dock Doors

- Types of Dock Doors (grade level, dock level with or without dock plates and types of dock plates)

- Age and Condition

- Existing Electrical and Networking Infrastructure

- Adequate Office Space

II) Determine Facility Processes and Areas

Once the Facility Requirements are identified, it is time to determine the Processes and Areas within the facility. Each facility is made up of many processes and areas, determined by the types of operations performed. Rather than trying to think about the processes and areas at a macro level, it is helpful to consider each major function and area within the facility individually – breaking each major process/area into the individual components they are made up of. Approaching the development incrementally, like this, is a more manageable way to ensure all are identified.

Common Processes and Functions Accounted For

A person intimately familiar with operations is most equipped to define these functions and processes. Seek to identify any opportunity to consolidate processes and functions, rather than having any type of repetition (waste).

- Receiving

- Repackaging / Labeling

- Putaway

- Picking

- Packing and Shipping

- Cycle Counting

- Crating

- Kitting

- Value Added Services

- Etc

Common Areas Accounted For

Like Processes and Functions, it is important to consolidate any area when possible. In addition to consolidating labor, you will also reduce the needed footprint by consolidating areas.

- Staging (inbound, outbound, etc)

- Receiving Stations

- Packing Stations

- Conveyor Runs

- Driver Reception

- Storage Areas

- Overages, Shortages, and Damages (OS&D) Holding Area

- Supplies Overstock Storage

- Local Data Center (Server/Networking Room)

III) Define Storage, Equipment, and Staffing Requirements

Once all Processes and Areas are identified it is time to determine the Storage, Equipment, and Staffing Requirements. It is important to determine each of these needs once the Processes and Areas are defined, to be sure an all-inclusive list of needs is created. The staff can only succeed if they are provided with the tools, equipment, and processes needed to achieve excellence. It is imperative that much thought is put into Storage, Equipment, and Staffing Requirements. This must be defined before proceeding to the layout design phase.

Considerations for Storage Requirements

- Types of Product

- Volume of Product

- Product Profile of Goods

- Stowability

- Size

- Weight

- Ordered Quantity (single, inner, master, 1/4 pallet, full pallet, etc)

- Accessibility

- Climate Control Requirements

- Limitations of Fire Code (regarding facility specifications)

Considerations for Equipment Requirements

- Types of Motors/Forklifts (storage methods and aisle width considered)

- Sit-down

- Stand-up Single Reach

- Stand-up Double Reach

- Cherry Picker

- Turret Truck / Swing Reach

- Aisle Master

- Electric Pallet Jack

- Conveyor (pneumatic, rollers, wheels, expandable, etc)

- Carts

- Ladders

- Tables

- RF Scanners

- Printers (Desktop and Thermal Labels)

- Scale (parcel vs floor)

- Shrink Wrap Machine

- Dimensionalizer (such as Cubiscan)

- Additional Specialized Equipment

Considerations for Staffing Requirements

- Number of Staff per Area or per Process

- Considering man hours per output

- Number of Leads, Supervisors, and Managers

- Opportunity to Cross Train between processes and areas

- Special Skill Requirements of Team Members (prior experience, ability to drive motors, etc)

IV) Determine Location of Areas Within Facility

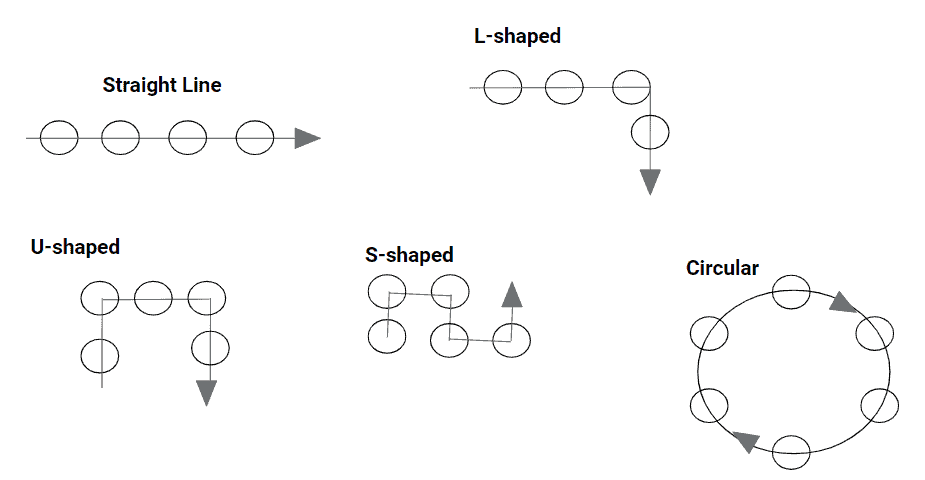

After all Processes and Areas are identified and all Storage, Equipment, and Staffing Requirements are determined, it is time to determine the Location of each area within the facility in relation to one another. The location of areas within the facility is critical to a smooth flowing operation, as traffic jams (backlogs) and increased travel times are the product of a poorly designed flow.

Considerations of Area Locations Within Facility

- Relationship of each area in regard to one another

- Areas that must be located close to or far from each other

- Consider using Activity Relationship Chart to evaluate

- Requirements of each Area

- Electrical and Networking

- Special Requirements – dock doors, climate control, clean room, secured location, etc

- Footprint

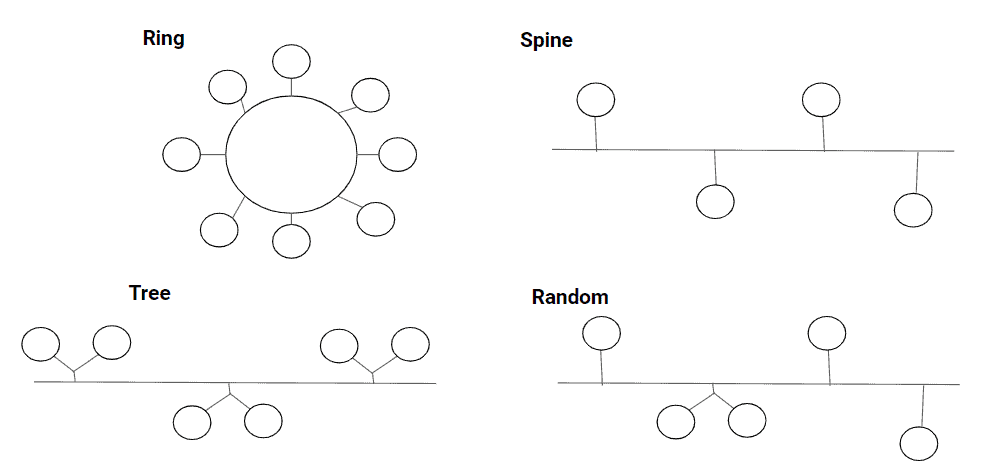

- Flow between Areas

- Maximize Direct Flow – No intersection or backtracking

- Minimize Flow – Reduce total flows and combine when possible

- Consider the flow patterns used between Areas

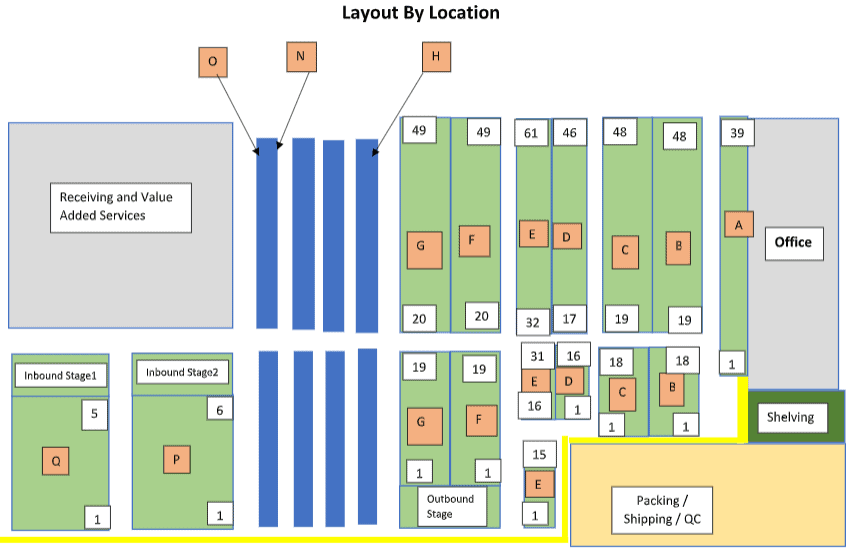

V) Put It All Together – Create the Detailed Layout

Finally the Detailed Layout is created. During this phase all earlier defined details are taken into consideration to produce a final drawing of the facility. This detailed layout accounts for the overall layout of the facility, and detailed design per area. It is best to create several variations of the Detailed Layout for comparison; this ensures the best possible design is selected for the operation.

Creating the Layout Drawing

- How the drawing is created depends on the situation and user’s skill

- Best case, an Auto CAD drawing is created that follows industry standards

- Can be hand drawn or some alternative technology if no technical skills – the details on the drawing are the important factor

- Drawing includes:

- Visual of areas located within facility

- Names/Labels of each area

- Measurements and dimensions of all elements of the drawing, the more detail the better

Additional Layout Creation Factors

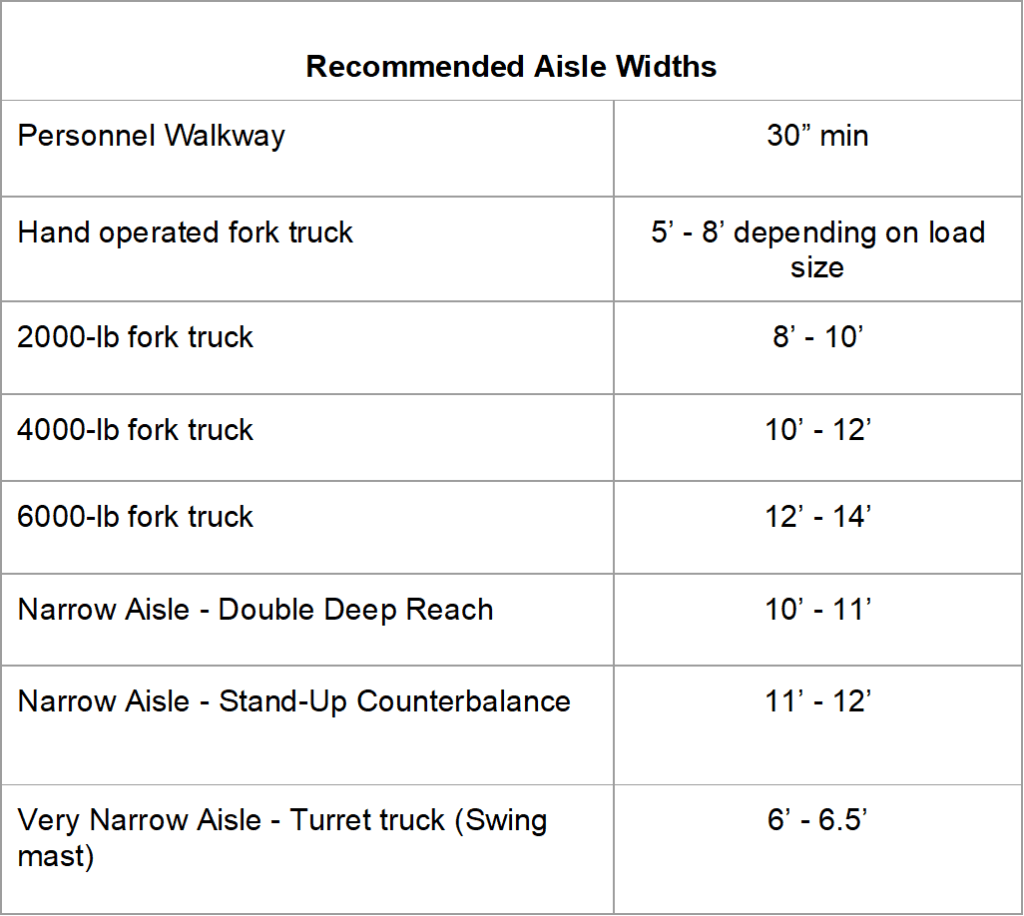

- Aisle Widths

- One-way or two-way traffic

- Equipment type used in aisle

- Pedestrian walkways

- Frequency of aisle use

*Aisle Width Source 1, Source 2, Source 3

- Flow Within Areas

- Like flow between areas, we develop the optimal flow within each single area

VI) Create Timeline and Assign Ownership of Milestones

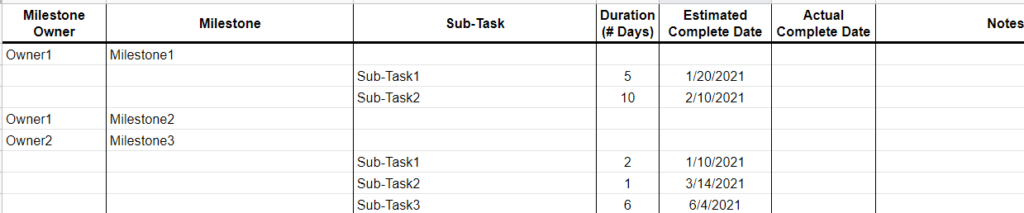

This phase should be completed at the beginning of planning, but is presented at the end of this article so that the reader understands the scope of Milestones that must be accounted for. Designing a new facility, or redesigning an existing facility is a large project so it is helpful to create a Project Plan or Milestone Tracker to monitor progress. Recording all Milestones and Details will ensure no details are missed, and that continual progress is made for a successful implementation.

Click for FREE Project Planning and Milestone Tracker Template

Considerations When Using Timeline and Milestone Tracker

- Must set REALISTIC expectation of Estimated Complete Dates and Duration

- Build buffer days into initial plan to reduce likelihood of missing deadlines and falling behind schedules

- ALL projects encounter delays!

- Ensure Milestone Owners understand expectations and scope of Completion

- Use Sub-Tasks when a Milestone requires multiple items to be completed

- During planning and implementation, continually reference Tracker to ensure on time and no items missed – this is the source of truth!

Conclusion

To recap, facility planning and operations layout is a vital component to running an efficient operation. The layout dictates the flow of work completed, and therefore has a major impact on future labor costs within the facility. Facility planning and layout design requires a thorough evaluation of requirements and operations.

First Geographic and Building requirements must be defined and evaluated against availability. Next all warehouse processes and areas are determined, this ensures that all needed operations and areas are accounted for in the design. Storage, Equipment, and Staffing requirements within the facility are then assessed. Now all areas within the facility must be evaluated to determine where they are located in proximity to each other, ensuring optimal flow is achieved. The final phase is creating the detailed layout design that contains all information and details required to implement the layout.

To aid in a successful facility design, or redesign, create your plan and track your progress using a Project Planning and Milestone Tracker. This tool ensures you account for all components of the project, and remain on schedule along the way. Don’t forget to build a buffer time into your planning, and set clear expectations with Milestone Owners!

What tips and tricks do you have for implementing an optimal facility design?

Share below!